- Aegan International DMCC

- Our Processes

RICE PROCESSES

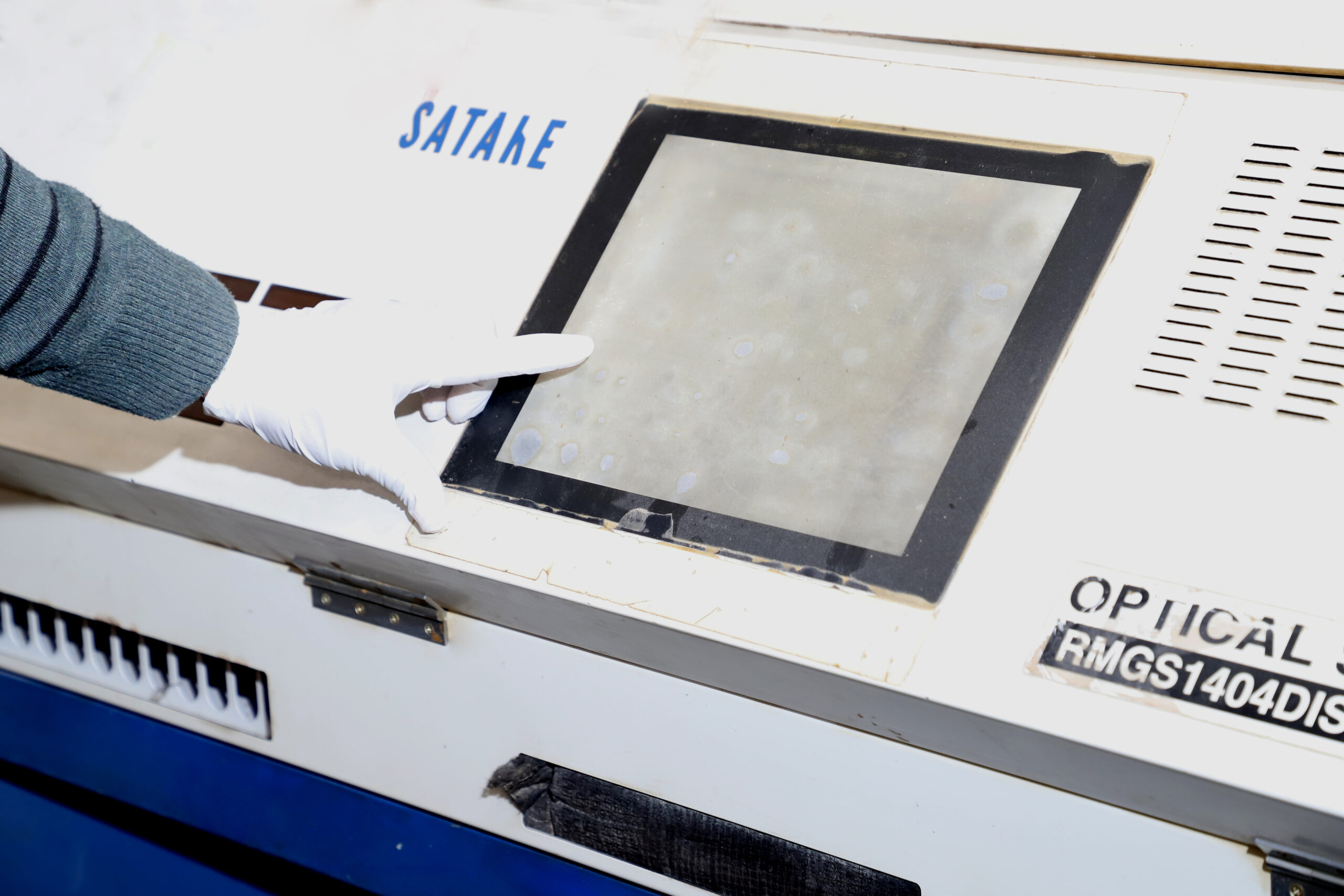

We fuse technology with our business operations to ensure that we are always a step ahead of our competitors. As a reputed agro-products Processer and exporter, our unit is laced with state-of-the-art industrial plant, procured from Buhler. We work with the belief that quality trumps all and our technologically advanced processes enable us to deliver nothing but the most premium quality rice, pulses, wheat & sugar to our global clientele. Our expert professionals make use of cuttingedge technology in the different stages from procurement to supply. Whether we talk about demoisturizing, temperature-controlled drying, cleaning, dehusking, destoning, polishing, sorting, or grading, the modern machines & advanced techniques employed by us help in completing all these tasks at the shortest time with full efficiency.

Our state-of-the-art equipment like precleaners, precision sizers, destoners, paddy separators, graders, dehuskers ensure that the grains we pack for export are not just uniform but their quality, aroma, and fragrance is also intact. Another range of equipment that makes our operation simpler, quicker, & streamlined include Lab De-huskers, Lab Kett Meters, Electronic Vernier Calipers, Paddy Separator, Precision Electronic Weighing Scales, & Labpolishers.

OUR WAREHOUSING UNIT

We have a spacious warehousing unit that enables us to store large quantities of rice, wheat, sugar, pulses, and other products in optimal conditions. We have equipped our warehouse with the essential amenities, advanced facilities, and state-of-the-art technologies to maintain the optimal condition for the storage of our products after procuring.

INFRASTRUCTURE

Aegan has maintained a highly equipped and advanced unit for the storage, quality testing, packaging, and dispatching of our products. Offering the highest quality rice, wheat, sugar, maize, pulses, & other grains is made possible with our milling, warehousing, and laboratory units.

PROCESS

Expertise in the industry, a promise of excellence, & smart strategic planning makes Aegan a leader in the exports industry of rice, wheat, sugar, and other agro-products. We keep a tab on the advancements in the industry to streamline, simplify, and speed-up our procurement to export process. We strive hard to push ourselves into attaining new levels of customer satisfaction with what we have to offer.

OUR LABORATORIES

At Aegan, we have a highly equipped laboratory that enables us to perform stringent testing on the products once they are safely brought into our unit. There are several advanced machinery and equipment running on the latest technology to ensure that our products are adhering to the international quality standards.

Download Our Rice Brochure

Tuna at Aegan

-

Tuna Canning and Packing Factory (Spanish Origin from the International Company Hermasa)

The tuna canning and packing factory has an estimated production capacity of 100 tons per day or about 300,000 cans of yellowfin tuna per day, sourced mostly from the Arabian Sea. Highly experienced teams are tasked to operate this line to ensure the quality and safety of the products.

-

The Refrigerator (Preparation Process of the Fish for Exporting)

The largest refrigerator was established to preserve, freeze and prepare fish for the production of frozen fish products to cater to both local and global demands. With the capacity of nearly 4,200 tons, the refrigerator supports the reception of large quantities of fish for export and for local production.

-

Oily Fishmeal Plant OFP55 (Thai Origin with European Specifications)

Oily fishmeal plant OFP55 is considered to be one of the best in the Middle East with an estimated production capacity of 55 tons per day. It is aimed to provide and enrich the international and local markets with the highest and best quality products. Technologies have been designed to ensure the safety of the manufacturing process and its eect on the environment and the population as well.

-

The Refrigerator (Preparation Process of the Fish for Exporting)

The crushed ice plant was established with the latest French Technology. The production capacity is about 22 tons per day, which can be doubled to 44 tons per day as the manufacturing capacity expands.

Manufacturing & canning stages

(1) Fish Receiving, Sensory Evaluation, Grading and Weighing

(2) Fish Gutting and Cutting

(3) Cooking by Steam

(4) Tuna Cooling

(5) Cleaning

(6) Tuna Canning

(7) Sterilizing Canned Tuna in the Auto Claves

(8) Casing and Incubation

(9) Conducting Test at Laboratory

(10) Brand Sticker Labelling and Packaging

TUNA Quality

-

The product quality has been taken into consideration which is our top priority. The quality system followed is subject to the European standards and regulations such as HACCP System and the International ISO Certificates.

-

What distinguishes Tuna at Aegan is the (Technology of Steam) steam cooking and sterilization system with the latest European technology from Hermasa. The waste disposal system is connected directly to the milling processing to producing the superb quality fishmeal powder.

-

We are keen on introducing smart systems that ensure the safety of the product, environment and the facility as well, so Smart Organization was introduced in order to keep pace with the developments and ensure continuous high-quality development throughout production periods.

-

• ISO 22000:2018 • ISO 9001:2015 • Certified Company

• HACCP( Hazard Analysis and Critical Control Point ) Certification For Food Safety Management Standard